GRS & SA8000® & ISO14001CERTIFIED COMPANY

GRS & SA8000® & ISO14001CERTIFIED COMPANY

GRS & SA8000® & ISO14001CERTIFIED COMPANY

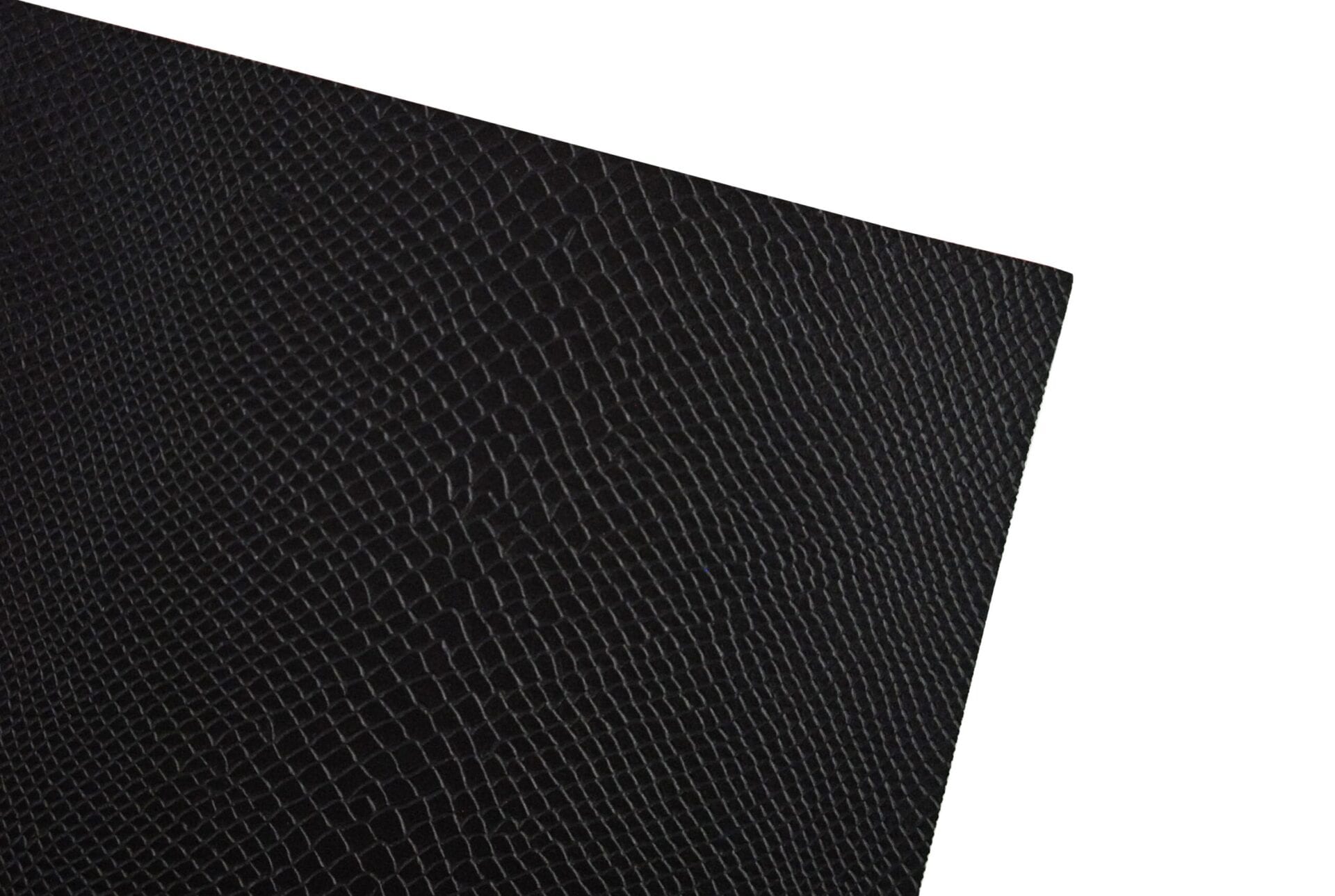

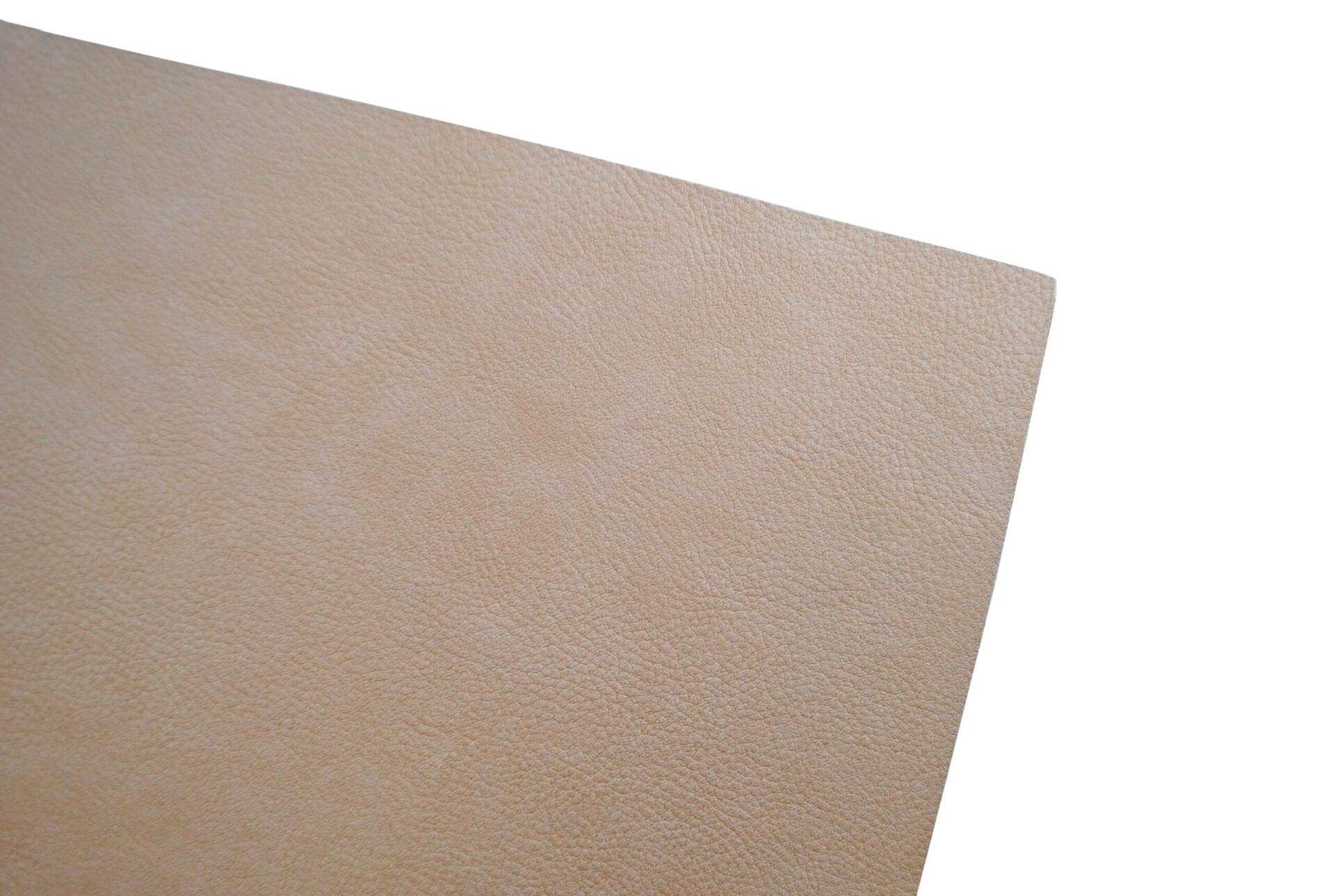

This innovative material is produced using a minimum of 59% recycled leather fibers, which give a consistency very similar to the real leather. It is the perfect combination between the need of recycling and establishing a sustainable process, with the fashion requirements of a very natural look. Thus, the external layer is produced with different materials, that confer the following looks, in a wide range of colours, identical to the real leather’s ones:

This innovative fabric, very similar to leather, is bio-based as it is made from apple fibers (obtained from organic industrial waste) then combined with polyurethane. This material is waterproof and breathable, resistant and even ethical not only because it is not of animal origin but also because it allows the exploitation of the waste from the industrial processing of apples. Specifically, peel and core are used, recovered from the industrial processing of organic apples.

After years of Research and Develpment the first highly sutainable and environmentally friendly alternative to leather made of cactus fibers has been launched, with a vast production capacity, color and texture large variety, meeting the most rigorous commercial quality standards. Main characteristics: Environmetally friendly, Low water use to grow our raw matter, Sustainable, Non-Irritant, Animal & environment preservation, Toxicity-Free, PVC Free, Unique Odor, Strong Tearing & Tensile strenght, Coliforms and fungi control, Customized textures & colors, Customizable thickness & Flexibility, Vast production capacity & Vast raw material, Easy to clean, Pigment Coloring, Free Phtalates.

Total Weight: g/m² 500 a 550

Thickness: mm. 0,88 a 1,2

Width minimum: m 1,37

This material has been conceived to be used as lining for footware and leatherware. It is made of bamboo-based non-woven fibers, which guarantee high breathability and optimal humidity absorption. The bamboo backing is coated with a layer of polyurethane, which confers a very good goatskin effect, high resistance to abrasion and to tension, and very high comfort. The thickness of the material is 0,60mm +/- 0,10mm.

The plant used is a tropical plant that grows on the banks of forest rivers. The «Alocasia Macrorrhiza» is born freely, not being cultivated. The choise for this plant was made by the combination of its beauty, availability and leaf dimension, wich ranges from 2sq ft to 5 sq ft. Plants produce leaves throughout the year. After the leaves are open, the yips of the leaves can reach up to 100 feet in height. Be-Leaf uses an entirely organic process. The water used in the process of «tanning» of the leaves, after treatment is returned to the fields surrounding the factory. The residues of production go to a process of decomposition (composting) and are reused as fertilizers.

The leaf used and treated is among the most innovative and ecological materials ever created. It has similar characteristics to the leather, surprisingly comfortable and resistant. We enriched the material with accessories made with: bioresin and recycled coconut produced by our company.