Country of the Footwear

Monte San Giusto

Monte San Giusto, footwear town.

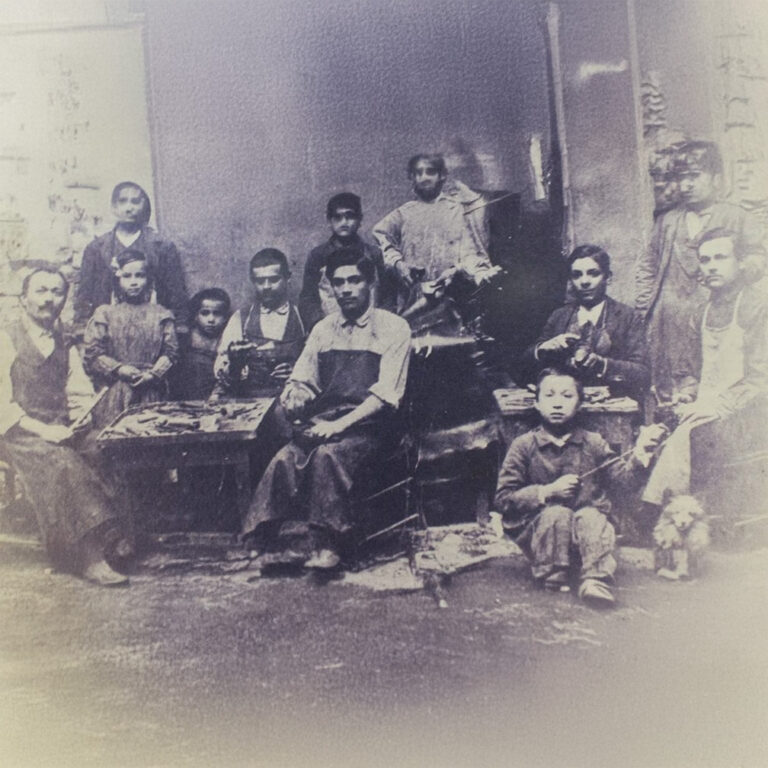

Recent studies about our area show that footwear activities started in Middle Age. Some researchers even went back to 1385 with the first Shoe Manufacturer Code Art of Shoemaking Status. Although , it is confirmed by a document that, since 1821, in Monte San Giusto land, there was a prosperous Shoe Maker School.

Through a census in 1901, it is possible to establish that, in Monte San Giusto, the employees in shoe field were about 323 (252 shoe makers, among who, 59 under the age of 15 years and 71 hemmers) over the total number of 821 citizens in the old centre, where were gathered about 40 craft shops. From 1920 to 1930, begins the Era of Technological Innovation, by the introduction of sewing machines which allowed the development of new styles, different from usual “clucks” or “slippers”. For boys were born “polish ankle-boots”, for girls “Ida’s pumps” with high heel, sleepers in wooden or cork heel. The production, step after step, loses roughness, takes form, style and elegance to be admired and sold in all the world, especially after the Second World War up to nowadays.

Leaving aside the contemporary history well known to everybody, characterized by the globalization of production, affecting the peculiarityís loss for many Italian footwear districts, it is interesting to illustrate briefly how the shoe was made in the origins.

Before describing all production phases, it is good to mention the fundamental tools used by our shoemakers.

A table (little desk) with a basement divided in different parts where to lay the needed tools for production: specific hammer, different types of clamps and tongs, eyelet pliers, small and big awls, lasts of different dimensions , cutter and whetstone to sharpen it, rasp, lime, pins (called seeds), strings treated with pitch for sewing the sole, water can to wet and soften the leather, carton and lots of glue to build up the sole. Women needed also draperies and light leathers to make the shoe upper.Since the first dawn lights, the chef craftsman, equipped with all his tools, started working, surrounded by all family members, including children and young trainees who, in order to learn the job, not only did not earn any money but, in addition, had to pay the owner of the craft shop for renting the space for the school and teaching them the job.

The Calzoleria of Monte San Giusto

Monte San Giusto, the Footwear Town.

The working day starts with the share of job duties by the chef and the fixing of the day quantity production. This plan is called tappa (stage), normally made of 6 pairs of leather shoes, 10 or 12 pairs if made of textile. The working day is not considered finished until the “tappa” is complete.

All made pairs are hanged on the wall or on the wooden beam of the laboratory. Each part of the shoe is handmade, as also the shoe upper which is hand-sewed by the woman assembling various pieces cut by the chef or by a chosen experience and trustful worker.The upper is built on the chosen mold and fixed on to the inner sole by spikes. This procedure is called bloccaggio (locking) After this important procedure, there is the fixing of the inner sole to a last layer of horse sole with glue, all sewed on the edges by hand. Up to 1930, shoe factories, intended as in modern language, did not exist yet, but were given to birth many crafts laboratories, as in the same area gathered components suppliers with all necessary tools for the shoe manufacturing: leathers, lining, strings, eyelets, seeds, yarns… A last note on transportation. Till that period of time, shoes, left and right side jointed, were delivered inside punching bags of different sizes. If present, the goods were shipped on railways otherwise by forwarders owning big wagons carried by strong horses, even though this method was slow and unsafe as easily attacked by bandits hidden in rugged and scrubbed roads.

This brief summery is drawn from the book : CENTONE SANGIUSTESE by Prof. Giuseppe Valentino Cipriani, to whom go our thanksgiving for the deep research, passion and survey released in his opera.